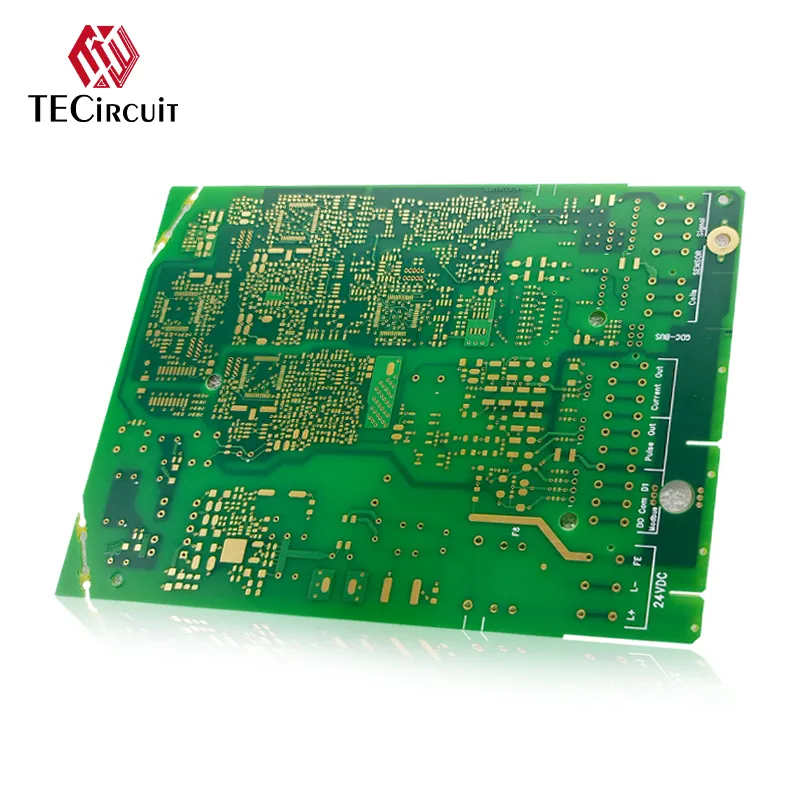

Arising Applications of Stiff PCBs in IoT and Wearable Devices

In the existing tech landscape, the demand for small yet trustworthy wiring options goes to an all-time high. This is particularly noticeable in the Internet of Things (IoT) and wearable gadget markets, where technology drives the market. One humble hero of this technical change is the RIGID Printed Circuit Board (PCB). Stiff PCBs are at the forefront of IoT and wearable gadget advancements, supplying durable systems for innovative electronic devices. This article checks out exactly how RIGID PCBs are gradually forming the future of gadgets that are pressing the borders of connectivity, benefit, and design.

Incorporating Inflexible PCBs in Next-Generation IoT Devices

The heart of any electronic tool is the PCB, and the duty of inflexible PCBs in IoT can not be overemphasized. Stiff PCBs provide stability and stamina that are vital in real estate components for numerous IoT applications. As IoT gadgets breakthrough in complexity and reduce in dimension, inflexible PCBs continue to be the best remedy for making certain the honesty of device framework while likewise making it possible for the integration of advanced sensing units and cpus.

Among the essential challenges in IoT design is accommodating sensing unit ranges, microcontrollers, and added electronics without compromising the device's durability or kind factor. Inflexible PCBs master giving the skeletal structure required to support these digital components. Their flat and stiff nature is perfectly matched to the demands of sensing unit combination and room optimization, which are important in IoT applications.

Resilience, Thickness, and Performance

Stiff PCBs are favored for their effectiveness, and when utilized with IoT tools in commercial or harsh ecological settings, they offer an unequaled level of defense against mechanical stress and thermal strain. The raising miniaturization of elements is enabled by the high density circuitry capabilities of stiff PCBs, enabling complicated wiring in a minimal area without sacrificing reliability or performance.

The Advancement of Wearables: Exactly How Inflexible PCBs Are Forming the Sector

In the world of wearables, we are experiencing an improvement from the confusing models of the past to sleek, practical devices that integrate perfectly right into our day-to-days live. This transformation is greatly driven by the flexibility of RIGID PCBs. Wearables need unique styles that can bend without breaking, and below, RIGID-FLEX PCBs stand apart.

Flexibility Without Concession

RIGID-FLEX PCBs incorporate the benefits of rigid and flexible circuits, permitting 3D forms and bends within a tool. pcb flex has allowed the advancement of wearables that comply with the contours of the body without endangering on the necessary connection stability. These developments have actually resulted in the creation of smartwatches, health and fitness trackers, and health displays that fit to put on and efficient in operation.

Power Monitoring Solutions for IoT Gadgets Using RIGID PCBs

Power effectiveness and power administration are crucial worldwide of IoT. Many IoT gadgets, particularly those running in remote or hard to reach locations, rely upon efficient use of power to keep longevity and decrease maintenance needs. Inflexible PCBs play an essential duty in optimizing power monitoring services, supplying a system for executing advanced power-saving modern technologies such as power gating, rest modes, and even energy harvesting.

Power Harvesting and the Function of Inflexible PCBs

Power harvesting is a game-changer in IoT, as it provides a method to power gadgets via the collection of ambient power sources like light, warm, and movement. RIGID PCBs with integrated power gathering components convert these collected energies into a secure power supply, extending the operational life of IoT gadgets without the requirement for regular battery substitutes or reenergizing.

Enhancing Connection Includes with Advanced RIGID PCB Layouts

Smooth connection is a specifying characteristic of IoT gadgets. RIGID PCBs sustain a host of connectivity features, consisting of innovative antennas, NFC components, and Bluetooth technologies, to guarantee perfect interaction in between devices and networks. The application of these technologies differs from smart home automation to commercial sensor networks, emphasizing the flexibility of RIGID PCBs in contemporary electronic devices.

Advanced Antennas and Signal Stability

For IoT gadgets to work ideally, their antennas need to be designed for the details frequencies and interaction criteria they will certainly use. Inflexible PCBs give a secure, interference-resistant system for these customized antennas, making certain that signal integrity is kept in a variety of usage situations. The assimilation of advanced antennas in RIGID PCB layouts promotes long-range communication and boosts the overall efficiency of IoT gadgets.

Security Considerations in IoT and Wearable Gadget PCBs

As the variety of connected tools proceeds to grow, so does the problem for security. pcba , when produced with high-security requirements in mind, supply a foundation that can support secure components such as TPMs and secure enclaves. Physical meddle resistance is one more inherent benefit, as RIGID PCBs are a lot more difficult to manipulate than their adaptable equivalents.

Designing for Security

Including protection functions into the PCB layout initially is essential. Inflexible PCBs, with their layer stack-up styles and controlled resistance routing, can serve as a barrier against invasion attempts. When incorporated with encryption and robust authentication methods, RIGD PCBs are important in guaranteeing that IoT and wearable devices are guarded against unapproved access and information breaches.

To conclude, inflexible PCBs are driving development in IoT and wearables by offering a stable and trustworthy foundation for innovative electronic devices. Their stamina, adaptability, and high-performance features make them an excellent choice for devices that need to operate in a vast array of conditions. As the IoT and wearable sector remain to develop, stiff PCBs will certainly continue to be a key enabler of the future generation of wise, linked devices.