Eco-Friendly Production: Linear Presses and Sustainability

In today's world, sustainability is an important part of producing methods. Industries require to take on modern technologies and devices that decrease their ecological impact while making certain the safety and wellbeing of their workers. Straight presses are one such technology that has actually reinvented the manufacturing sector. Linear presses give various advantages, consisting of reduced waste generation, improved safety in the workplace, and reduced power consumption. In this blog site post, we will examine the different environmental and safety and security aspects of linear presses and their duty in contemporary manufacturing.

1. Guaranteeing Safety And Security in the Work Environment with Linear Presses

Safety is a top concern in any type of workplace, particularly in manufacturing. Direct presses are made with numerous precaution to lessen the risk of mishaps and injuries. For example, they have emergency situation stop switches that can promptly stop operations in case of a problem. Additionally, linear presses have caged working locations that keep operators risk-free and stop crashes. In addition, straight press makers likewise supply maintenance and security training to guarantee that personnel know just how to run the devices properly. By embracing linear presses, industries can substantially enhance worker safety and security and protect against crashes, resulting in an extra lasting and liable workplace.

2. The Function of Linear Presses in Reducing Industrial Waste

Manufacturing markets create a considerable amount of waste, which can harm the atmosphere and influence human health and wellness. Linear presses are made to lessen waste generation in many means, consisting of using exact cutting procedures and the efficient use of resources. For example, when making auto components making use of typical production methods, there are normally large areas of extra products and inefficient cutting procedures. On the other hand, linear presses utilize precision cuts to make useful components from basic materials, minimizing wastefulness. This reduction in waste causes lower energy usage, decreased landfill use, and reduced greenhouse gas discharges. Linear presses, therefore, play a crucial duty in promoting ecological sustainability by decreasing industrial waste.

3. Compliance and Regulations: Linear Presses in the Global Market

In today's global markets, sectors need to adhere to different policies and guidelines to safeguard the atmosphere and guarantee employee security. grinding wheel machine are made with stringent compliance standards to satisfy these guidelines. As an example, the European Union applied the Constraint of Hazardous Materials (RoHS) instruction, which intends to restrict using unsafe products in electronic devices making. Direct press makers have actually guaranteed their products can adhere to RoHS and various other regulatory demands. Firms that purchase straight presses can have self-confidence in their compliance and can preserve their reputation as liable and lasting traders.

4. Innovations in Linear Presses for Lowered Environmental Influence

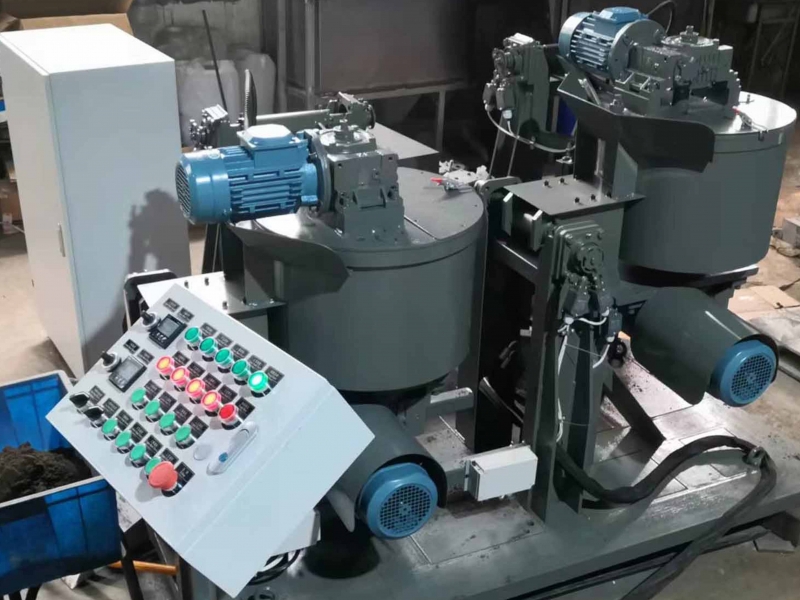

Direct presses have undergone substantial developments to improve their environmental influence continually. For instance, producers have actually established hybrid drive systems that utilize less power, tankless hydraulic systems that decrease oil use, and direct-drive motors that get rid of transmissions. Moreover, innovations in making use of light-weight products and alternative energy sources in straight presses have actually significantly reduced their environmental footprint. The demand for more sustainable manufacturing techniques has actually stimulated further development in straight presses, resulting in the creation of more effective and green makers.

Finally, straight presses provide an even more sustainable and responsible production strategy that reduces waste, improves worker safety, and reduces power usage. The developments in these machines have enabled industries to boost their environmental sustainability, adhere to regulations, and decrease their carbon footprints. grinding wheel machine that embrace straight presses can position themselves as accountable and sustainable traders by protecting the environment and guaranteeing employee security. Without a doubt, the future of manufacturing is connected to embracing sustainable technologies like straight presses, and it is extra required now than ever.