Emerging Applications of Inflexible PCBs in IoT and Wearable Devices

In the current technology landscape, the demand for compact yet reliable wiring remedies is at an all-time high. rigid flex pcb is especially apparent in the Internet of Points (IoT) and wearable tool industries, where innovation drives the market. One humble hero of this technological revolution is the RIGID Printed Circuit Board (PCB). Inflexible PCBs are at the center of IoT and wearable tool developments, giving robust platforms for advanced electronics. This post discovers how stiff PCBs are gradually forming the future of devices that are pushing the limits of connectivity, comfort, and layout.

Incorporating RIGID PCBs in Next-Generation IoT Devices

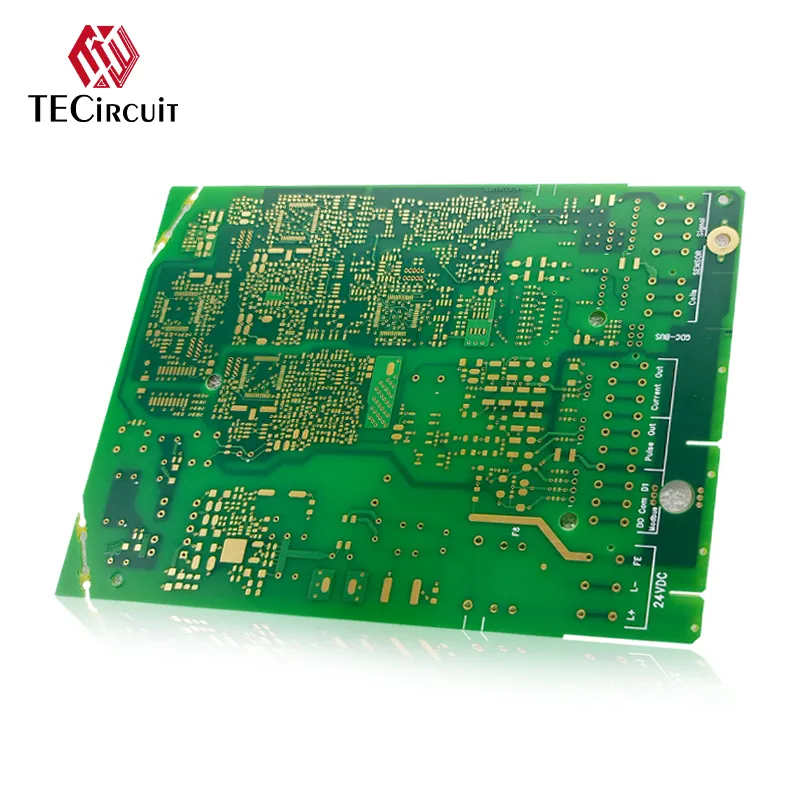

The heart of any type of electronic tool is the PCB, and the duty of inflexible PCBs in IoT can not be overstated. tecircuit offer stability and toughness that are crucial in housing elements for different IoT applications. As IoT devices breakthrough in complexity and diminish in size, RIGID PCBs remain the go-to service for guaranteeing the honesty of device structure while likewise allowing the combination of innovative sensing units and cpus.

Among the key obstacles in IoT design is fitting sensing unit selections, microcontrollers, and extra electronics without endangering the device's sturdiness or type element. RIGID PCBs master supplying the skeletal framework necessary to support these electronic aspects. Their flat and rigid nature is completely suited to the demands of sensor assimilation and space optimization, which are essential in IoT applications.

Toughness, Density, and Efficiency

RIGID PCBs are preferred for their robustness, and when made use of with IoT tools in commercial or severe environmental settings, they provide an unmatched degree of defense versus mechanical tension and thermal strain. The enhancing miniaturization of components is made possible by the high density wiring capacities of stiff PCBs, enabling complicated wiring in a restricted area without giving up integrity or efficiency.

The Evolution of Wearables: Just How Inflexible PCBs Are Shaping the Industry

In the world of wearables, we are experiencing a transformation from the clunky models of the past to sleek, practical devices that integrate perfectly into our day-to-days live. This transformation is mostly driven by the versatility of inflexible PCBs. Wearables require one-of-a-kind designs that can flex without breaking, and below, RIGID-FLEX PCBs stand out.

Adaptability Without Compromise

RIGID-FLEX PCBs combine the advantages of inflexible and adaptable circuits, permitting for 3D forms and bends within a gadget. This transformative step has made it possible for the development of wearables that adapt the contours of the human body without compromising on the required connection honesty. These improvements have brought about the creation of smartwatches, health and fitness trackers, and health and wellness displays that fit to use and effective in operation.

Power Administration Solutions for IoT Instruments Making Use Of Stiff PCBs

Energy effectiveness and power administration are crucial on the planet of IoT. Most IoT tools, specifically those running in remote or inaccessible locations, rely upon effective use energy to preserve longevity and reduce upkeep requirements. Inflexible PCBs play an essential duty in optimizing power management solutions, supplying a platform for executing advanced power-saving technologies such as power gating, sleep settings, and even energy harvesting.

Power Harvesting and the Role of RIGID PCBs

Energy harvesting is a game-changer in IoT, as it gives a means to power tools through the collection of ambient energy resources like light, warmth, and activity. Inflexible PCBs with incorporated energy harvesting components transform these gathered powers right into a steady power supply, prolonging the functional life of IoT devices without the requirement for regular battery replacements or reenergizing.

Enhancing Connectivity Features with Advanced RIGID PCB Designs

Seamless connection is a specifying characteristic of IoT devices. Stiff PCBs sustain a host of connectivity features, including advanced antennas, NFC components, and Bluetooth technologies, to guarantee flawless communication between gadgets and networks. The application of these technologies varies from clever home automation to industrial sensor networks, highlighting the versatility of inflexible PCBs in modern-day electronics.

Advanced Antennas and Signal Stability

For IoT tools to work efficiently, their antennas should be designed for the specific frequencies and communication requirements they will certainly utilize. Inflexible PCBs offer a secure, interference-resistant system for these tailored antennas, ensuring that signal integrity is maintained in a selection of use scenarios. The combination of sophisticated antennas in inflexible PCB layouts helps with long-range interaction and boosts the total efficiency of IoT gadgets.

Safety Considerations in IoT and Wearable Gadget PCBs

As the number of linked gadgets proceeds to expand, so does the issue for security. Inflexible PCBs, when produced with high-security standards in mind, use a foundation that can sustain secure aspects such as TPMs and safe territories. Physical tamper resistance is another intrinsic advantage, as inflexible PCBs are a lot more tough to manipulate than their versatile equivalents.

Creating for Security

Including safety and security functions into the PCB style at the beginning is essential. Inflexible PCBs, with their layer stack-up styles and controlled insusceptibility transmitting, can work as an obstacle versus invasion attempts. When integrated with file encryption and durable authentication procedures, RIGD PCBs are essential in making sure that IoT and wearable gadgets are secured against unapproved accessibility and information violations.

Finally, inflexible PCBs are driving technology in IoT and wearables by providing a secure and trusted structure for innovative electronics. Their toughness, adaptability, and high-performance attributes make them an optimal selection for gadgets that need to operate in a variety of conditions. As the IoT and wearable sector continue to advance, inflexible PCBs will most certainly remain a vital enabler of the future generation of smart, connected devices.