Leveraging Precision: Advantages of Linear Strike Presses for Metalworking

Sheet steel manufacture demands a fragile equilibrium of power and accuracy. As modern-day market proceeds to push the borders of design, the role of machinery in achieving the highest requirements of stability and accuracy has actually never ever been more critical. In Zhengzhou Hongyi Machinery , we'll explore the benefits of incorporating linear strike presses into your metalworking strategies, from the auto mechanics that make them exceptional to hydraulic counterparts, to the security improvements and longevity of your equipment.

The Mechanics of Linear Punch Presses in Accuracy Sheet Metal Construction

The term 'straight press' might stimulate concepts of basic, unidirectional motion, yet the fact is a harmony of auto mechanics at the office. Unlike the fluid and occasionally imprecise movements of hydraulic systems, straight presses operate with a single-minded goal: precision. Each activity is managed by a direct linear drive, ensuring that the pressure exerted on the material is specific, foreseeable, and repeatable.

In metalworking, also the smallest variance can lead to pricey errors. A linear punch press provides the security needed for detailed cuts and forms, with marginal run-out. This means every item that leaves your workshop is within resistances, staying clear of the requirement for rework and guaranteeing the high quality your clients need.

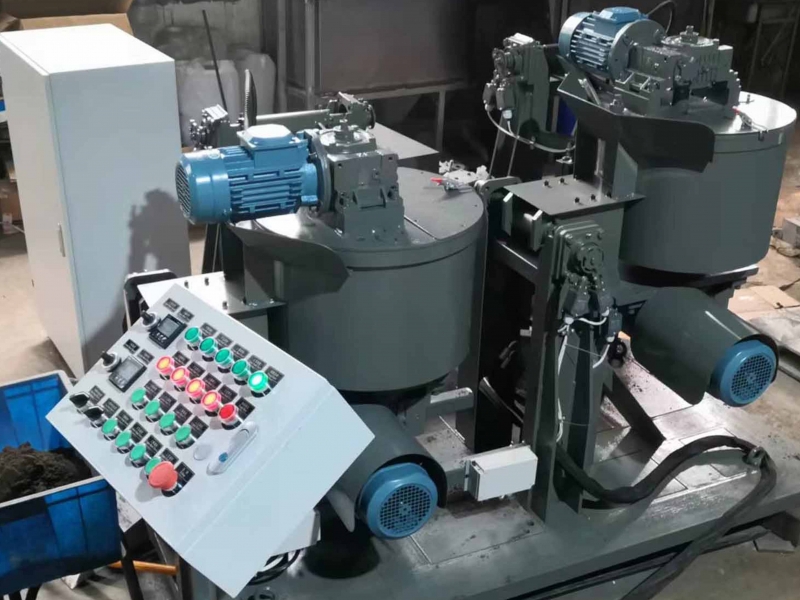

When you utilize a Linear Press 150-230mm, as supplied by ZZHongyi Equipment, you are harnessing the power of programmable digital controls that can do intricate maneuvers with remarkable ease. These advanced systems enable rapid prototyping and fast adjustments, lowering downtime and accelerating the manufacturing cycle.

Maximizing Your Workshop Room: Compact Style of Linear Strike Presses

Area is at a costs in many manufacturing atmospheres, and every square inch counts. Conventional hydraulic presses often include a significant impact, demanding bigger workspace and decreasing the total performance of the space. Direct punch presses have progressed to be more small, without compromising any power or efficiency.

mixer machine minimized size of direct presses means that your drivers have even more area to maneuver, workstations can be enhanced for operations, and your workshop can suit additional devices needed for complementary processes.

The portable design of a Linear Press 150-230mm additionally makes it an appealing choice for organizations seeking to broaden their capabilities without expanding their facilities. This flexibility permits you to grow your metalworking operations without major disturbances or costly movings.

Security First: Advancements in Safe Procedure with Linear Strike Press Machinery

The extreme nature of metalworking can position considerable safety dangers otherwise handled properly. Direct punch presses attend to these concerns with innovative safety features that are built-in and non-negotiable. Interlacing systems, light curtains, and ergonomic designs shield operators from moving components and ensure their well-being.

With determined and configured procedures, the opportunities of driver mistakes are dramatically lowered, and complete training can be focused on exact actions as opposed to operational obstacles. Safety and security isn't just a concern; it's a component of the manufacturing flow, encouraging confidence and performance amongst your group.

Attaining the equilibrium between performance and safety and security is not just a lawful need however an ethical commitment to your labor force. Direct punch presses symbolize this viewpoint, making a dedication to efficiency that does not jeopardize the wellness of those that keep your operation running.

Material Benefits: Expanding the Life of Tooling with Linear Press Techniques

In the relentless globe of metalworking, tooling is your toolbox, and preserving its stability is a constant battle. The force and repetition entailed in marking and punching are a warranty of wear, but with a direct press, this can be specifically managed and reduced.

The straight linear movement of the ram minimizes damage not just on the devices but additionally on the press itself. With appropriate upkeep, the life process of your tools is extended, and the total cost of possession is dramatically minimized.

Straight punch press modern technology has actually also made strides in material handling. Scrap parts and materials are expelled promptly and effectively, stopping back-pressure build-up that can harm devices and impact the total item quality.

Choosing the Right Linear Punch Press for Your Metalworking Requirements

Selecting the appropriate direct press is a choice that needs to not be ignored. Considerations such as the thickness of the sheet metal you deal with, the ins and out of the styles you create, and the volume of your manufacturing are simply the beginning.

The Linear Press 150-230mm offered from ZZHongyi Machinery is a superb starting point, but customizations and added attributes may better fit your operation. Consult with production professionals and the service providers straight to analyze your special needs and locate the excellent match.

Buying a straight punch press is an investment in the future of your metalworking capabilities. The advantages it generates precision, area, safety and security, and longevity are not just immediate but additionally enduring. As you evaluate the perspective of your sector, a direct strike press might be the trick to unlocking brand-new elevations in your organization.