Optimizing Sheet Steel Construction for Sustainable Manufacturing

In the context of our progressing ecological awareness, lasting production has ended up being greater than just a memorable expression-- it's an obligation that the market must shoulder. One sector that's climbing to the obstacle is sheet steel construction. This procedure, integral to producing components for a range of items, can be maximized for sustainability in a myriad of ways. Below's a deep-dive into how the sheet steel manufacture market is forging in advance with green practices without compromising on top quality.

Eco-Friendly Practices in Sheet Metal Construction

For sheet metal construction to be lasting, the beginning factor has to be an aware initiative to reduce the environmental influence of the procedure. This consists of everything from equipment and material choice to ditch reduction and energy-efficient procedures.

The Role of Recycled Products in Modern Metal Sheet Production

One of one of the most considerable shifts in the direction of sustainability has actually been the assimilation of recycled products into the manufacturing of metal sheets. These products, usually junk steel from previous production processes, reduce the need for brand-new ores, thereby saving all-natural sources and energy. The industry is increasingly purchasing tools that can handle a greater proportion of recycled content, making sure that every sheet that's cut and bent is a step in the direction of a greener future.

Decreasing Waste through Effective Sheet Steel Layout and Nesting

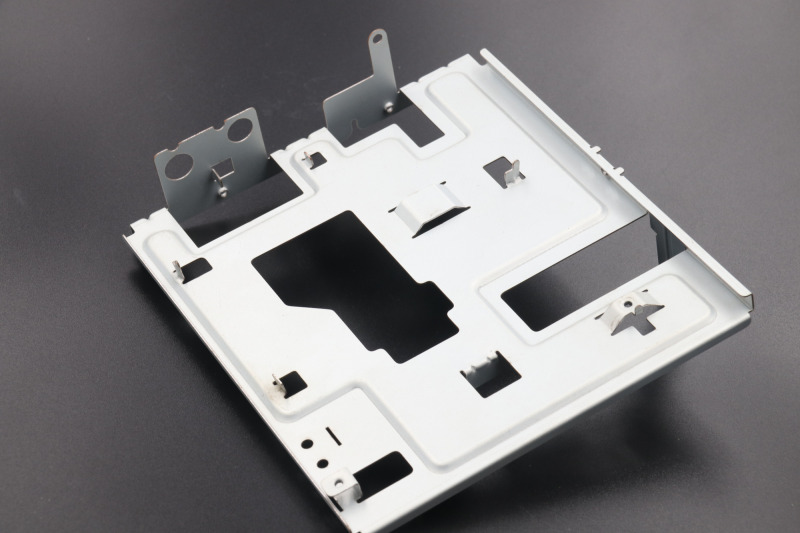

Waste decrease begins with style. By utilizing lean concepts and progressed computer system modeling, fabricators can produce effective part layouts that decrease the amount of unused material. Nesting software program even more optimizes this procedure by organizing private parts in such a way that reduces scrap and enhances the variety of components that can be produced from a solitary sheet. These simple however reliable methods can cause a significant decrease in product waste.

Energy-Saving Technologies in the Sheet Steel Industry

The sheet steel market typically eats a big amount of energy as a result of the high temperature levels required for cutting, developing, and finishing. However, advancements in modern technology offer remedies that substantially minimize energy consumption without sacrificing productivity.

The Adoption of Laser Cutting and High-Efficiency Presses

Laser reducing, with its accuracy and reduced material bending, is not just a game-changer in terms of top quality however additionally in energy performance. Contrasted to typical mechanical reducing techniques, lasers take in less power and generate less product waste. In a similar way, high-efficiency presses require less energy to develop steel, and when incorporated with energy healing systems, can lead to significant financial savings.

Renewable Energy Combination

Numerous forward-thinking sheet metal construction centers are moving in the direction of or have currently implemented eco-friendly energy resources, such as photovoltaic panels and wind generators, to power their operations. This not just decreases the greenhouse gas emissions connected with standard power generation but additionally guards manufacturers from the volatility of nonrenewable fuel source prices. In addition, some are transforming to green energy tolls, which sustain the generation of sustainable power.

Sustainability in Powder Coating Processes

Powder finishing, the process of applying a completely dry powdered paint to a steel part, is one more location where sustainability can be substantially boosted. Typical fluid paints usually contain high levels of unstable organic compounds (VOCs), which can be harmful to the environment and human health and wellness.

Low-Emission and VOC-Free Powder Finishing Formulations

The market is swiftly moving in the direction of low-emission and VOC-free powder layer options. aluminum cnc machining service provide the very same level of security and coating as their standard equivalents however with a portion of the ecological impact. For producers, this implies not just a cleaner conscience however a much safer and healthier work environment for staff members.

Efficient Application and Waste Healing Systems

The application of powder layer can be enhanced to reduce overspray and make the most of transfer performance. In addition, waste healing systems can capture and reuse excess powder, lessening the amount of product that ends up in land fills. These cooperations not only lower waste however likewise decrease the general consumption of powder finishings.

By implementing plastic cnc milling and modern technologies, the sheet metal manufacture industry is not just speaking about sustainability-- it's proactively functioning towards it. Each action taken, from the design procedure to the finishing touches, figures in in preserving resources and preserving our world for future generations. The road to sustainable manufacturing might be long, but the sheet metal industry is proving that with innovation and decision, every industry can find its method.